Goodland England is the home of Rolls-Royce motor cars, a brand known for its meticulous design, engineering, and craftsmanship when it comes to endowing cars with an ethereal beauty. Their famous automobile products like Rolls-Royce Phantom, Wraith, and Ghost are considered no less than a supercar, but here super implies more luxury than speed.

We are not going to get into too much detail; the making of Rolls-Royce Phantom is a very elaborate process that takes painstaking accuracy and care. In this automobile article, we will cover the parts that define its luxury and artistic inspiration behind it. The main point being the use of human craftsmanship than robotic assembly lines that we see in luxury electric cars like Tesla Model S. Rolls-Royce supercars are meant to highlight art more than their technology and engineering.

Rolls-Royce Company: Short History

Charles Rolls was at Cambridge where he was a key aviator while Frederick Royce was a son of a miller who started provided income support for his family at the age of 9. The contrast between founders of the company couldn’t have been more dazzling. In 1904, the unlikely duo began to form an alliance driven by their love of art and engineering, and Rolls-Royce (RR) came to life. Sadly, Charles Rolls’ death ended the amazing partnership between the car lovers, but he did not die before eternalizing by help designing what was known as the best in the world: The Silver Ghost.

In 1925, Rolls-Royce started the design changes, which carried out a long tradition of ever-evolving outlandish car models. In 1998, Rolls-Royce was acquired by German automaker BMW, which gave a super-boost to the subsidiary by providing a completely re-imagined manufacturing plant.

Birth of Rolls-Royce Phantom

BMW took the covers of Rolls-Royce Phantom in 2003, giving the luxury car brand its modern identity as a high-tech carmaker.

THE MAKING OF ROLLS-ROYCE PHANTOM

Chassis

The behemoth chassis of Rolls-Royce Phantom is manufactured in Germany and then shipped to the Goodwood plant, all the 2k welds (about 100 meters in length) are carried out by hand. Lightweight Aluminum and alloy combination makes it very light and very strong at the same time, without compromising frame’s dynamicity.

Paint shop

A total 22-stage process gives the luxury car its breathtaking finish, which involves the careful rendering of 5 layers of paint carried out over an entire week just to make Rolls-Royce Phantom a luxury ride. Hand craftsmanship matters here because over 45 kilograms of body paint is sprayed on manually by highly skilled paint technicians so that no corner goes without getting colored.

Then two paint robots apply a layer of primer, necessary for shielding the metal against UV light and metallic corrosion. In the process, the robotic arms open and close the various panels of the body so hard to access parts like joints and internal skin of the body panels can be perfectly rendered with the primer coat, with just the right thickness. [3 steps of coatings still remain]

THE MAKING OF RR PHANTOM INVOLVES NO MORE THAN A TOTAL 4 ROBOTS

In the making of Rolls-Royce Phantom, the color coating breathes colors to life while the glossy clear coating liquor creates a mirror like finish. 16 colors with 44 thousand paint hues mean incredible countless combinations according to the customer’s personalization choices, making it the most color-customizable luxury car ever.

Once the painting process is complete, surface finishing experts come into action; ultra-fine grade sandpaper is used to smoothen the surface; buffers with special cleansers are used to clean it up and finally clothes are used to remove any speck of fingerprints. This gives the Phantom a shield against corrosion and time decay while the beautifying its surface reflective looks. [the process takes about five hours with multiple experts dedicatedly clung to the car.

Coach line (3 hours)

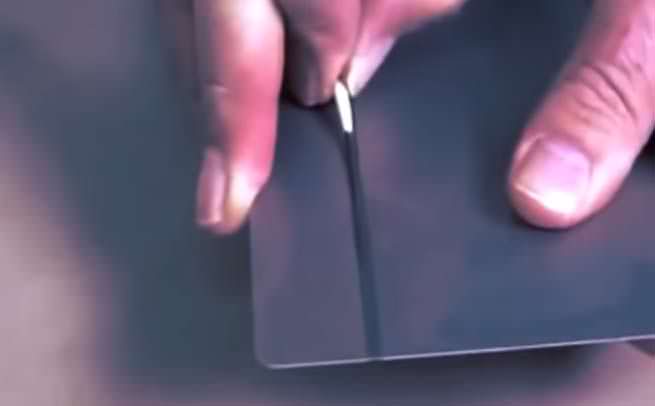

The trademark coach line (a decorative line on the bodywork of a motor vehicle) of the Phantom is sketched through an awe-inspiring process, conducted by just one man whose job is to draw it with perfection. Interestingly, as the coach line experts apply the glass enamel paint using a miniature paintbrush made up of squirrel hair.

The result is a delicate and unreal 6-meter coach line on the body shell that makes Rolls-Royce Phantom stand apart from coach line illustration in any other luxury car.

Dashboard & Interior

Exotic vinyl collection from around the globe is used to decorate the frontal impression of the cockpit in the form of an ethereal and satisfying-to-look-at wooden finish. First, the vinyl humidified so it’s natural crispiness doesn’t break it during the manufacturing process. Again, with 2k wood vinyl combinations to choose from, the customization here becomes even more contrasting.

Total 42 wood parts make up the Phantom’s interior. A series of wooden sheets and adhesive sheets are piled up and pressed together under heat and pressure to form the basis of the piece of wood. Thickened sheets resulting from the bonding

Dashboard frame is also shaped from a wooden block of tough wood, trimmed and cut to fit in the Phantom’s dashboard space, where so vinyl sheets can be pasted on it later.

Dashboard panels are also crafted from vinyl by hand using workstations that are covered by velvet to prevent even minor scratches.

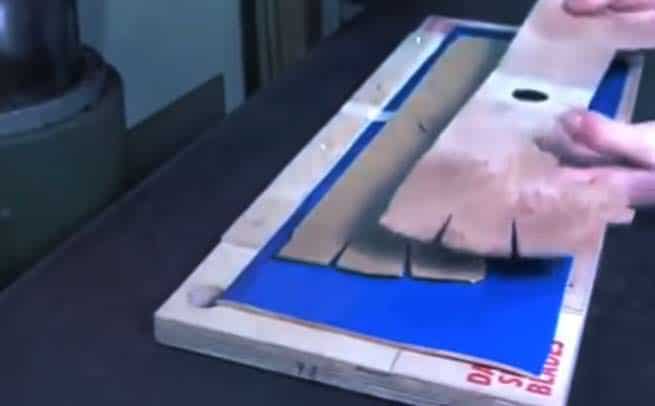

After aligning smaller pieces together, the larger sheets are covered with blue protective sheets before the required shape is extracted out with the help of a machine.

Next, the hard frame components are applied wood glue and flexible vinyl sheets, cut accordingly, are pasted onto them. A 45-min suction treatment perfectly fixes the bondage.

Vinyl sheets are now fixed on the hard wooden frames and the blue protective sheet is removed on another workstation.

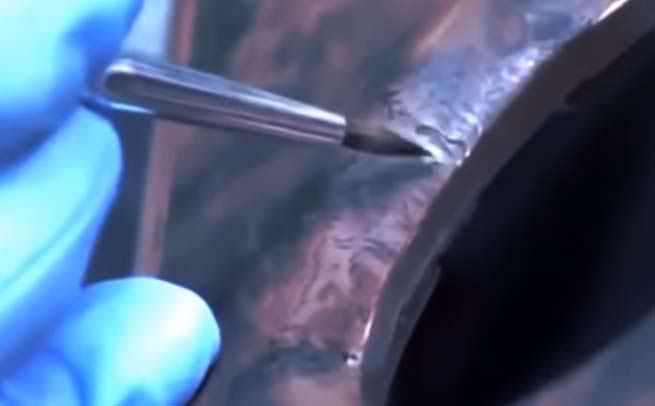

Expert workers carefully observe any cracks in the vinyl sheets and fixed with bonding glue and matching material. This involves fine-filing of the surface so the repair cannot be distinguished by the most discerning eyes, clearly a work of consummate craftsmanship.

Now the dashboard components are ready, but another round of (color) fixation is carried out on the vinyl areas that don’t match the car owner’s designated color scheme. This is done by hand using a fine paint brush and fast drying paint oils, repeatedly, until the painted design matches vinyl’s natural pattern so the final result is flawless. The re-colored dashboard pieces are left to dry for 45 minutes so the paint settles deep into the vinyl skin.

The final glossy appearance of the dashboard pieces is achieved using a power buffer. Now the dashboard is ready for assembly, but before that, electrical components must be fixed onto them individually.

IT TAKES 17 DAYS TO COMPLETE ROLLS-ROYCE PHANTOM’S INTERIOR

After electrical set up, the dashboard components are installed inside the Rolls-Royce Phantom cabin.

Leather trim

The leather interior of the Rolls-Royce Phantom has to be flawless and to make sure the bull hide is immaculate, it is placed one a stretcher that enables a worker to pinpoint and mark holes, scratches, stretches, mosquito bites, and any other impairment so that part of the leather cannot be used.

11 BULL HIDES ARE USED TO MAKE A TOTAL 450 PIECES OF LEATHER FOR A SINGLE LUXURY CAR

The analyzed hides are placed on a laser cutting station and a computer is used to take the maximum advantage of the available piece and cut the interior pieces leaving the impaired areas out, which are later discarded.

The leather piece that is to cover up the headrest is stitched with the iconic Rolls-Royce’s double R emblem. Although the stitching is carried out with a computerized machine, a dedicated seamstress is responsible for certifying the perfection of each emblem.

Once the Rolls-Royce emblem for the Phantom is complete, dozens of seamstresses in a sewing room stitch together the rest of the leather seat covers and other parts of leather upholstery.

The leather headrest cover is carefully given its innards (foam and metallic shafts that respectively form soft and hard parts of its frame) while workers deployed on rest of the seat’s body complete the leather encapsulation of the luxury seats.

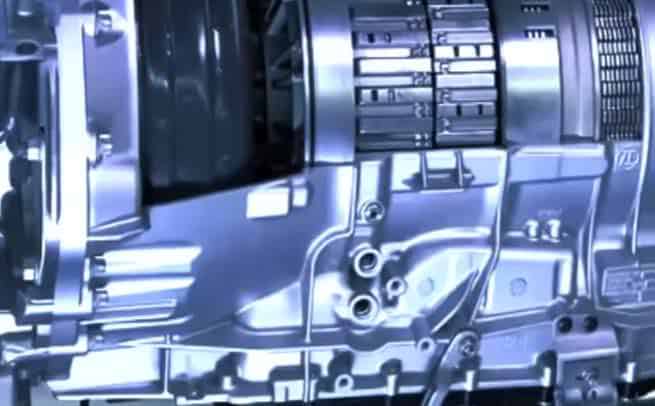

Installation of Engine and Drivetrain

450 horsepower v12 engine; 100 km/h in just 5.9 seconds; 8-speed automatic gearbox.

Both the engine and the series of components that deliver its power to the wheels (drivetrain) are installed on an assembly line that uses both robotic and human help. This involves,

- Putting together the rear and front axil, and placing the engine (plus gearbox) above the front axil.

- Engine components like the radiator and driveshaft are installed and the dynamic frame that drives the Phantom is united with its body, hence the process is called ‘The Marriage.’

- Various components (brakes etc) are checked at this stage, windshield and glass work is fitted and cleaned, aluminum alloy tires are installed.

The Spirit of Ecstasy

Spirit of Ecstasy, also known as the flying lady, was designed in 1911 and gives Rolls-Royce its unique identity. The statue is a single component that never changes its shape throughout the brand’s luxury car offers. However, in Rolls-Royce Wraith, the Spirit of Ecstasy leans 5 degrees forward to indicate that Wraith is the fastest of all the cars. Spirit of Ecstasy is installed on a special retractable platform to protect is from the thieves. The front grill is installed afterward a 5-hour polishing and coverage with a protective sheet.

Monsoon Testing

Now almost ready Rolls-Royce Phantom is showered in a simulated Monsoon rainwater to detect in water leakage seeping into the cabin.

Dynamo Testing

Dynamo tests are comprised of performance check for the gGearbox, suspension and braking, engine power and torque. The specially designed dynamo is able to simulate various road conditions and difficulties so every car is carefully analyzed.

THE ENTIRE ASSEMBLY TAKES 2 MONTHS TO COMPLETE

Making Rolls-Royce Phantom: Summary

We skipped the more mechanical processes like the making of Rolls-Royce Phantom’s engine because it is essentially just metallurgy and is no different than how engines of other cars are made.

Rolls-Royce is a modern piece of art that might disappear in the future as electric cars are rising or it could adopt the electric drivetrain at the price of its size and heavy elements that make it beautiful. It doesn’t matter who is the owners, the Phantom is the result of manual touch and human craftsmanship, evident by the wow gaze of onlookers. It makes you go wow, because while its beauty won’t last forever, what’s important is it is created to be beautiful and is meant to be loved.sup